Behind the Scenes: Mit ihrem ausgesprochen schlanken E-Bike waren die Österreicher von Geero 2016 ihrer Zeit um einiges voraus. Aber nicht nur das Produkt selbst ist spannend: Dieser Innovationsgeist lässt sich nämlich auch beim Blick hinter die Kulissen erkennen. So setzt man beispielsweise voll auf „Made in Austria“ und legt großen Wert auf regionale Wertschöpfung und Nachhaltigkeit.

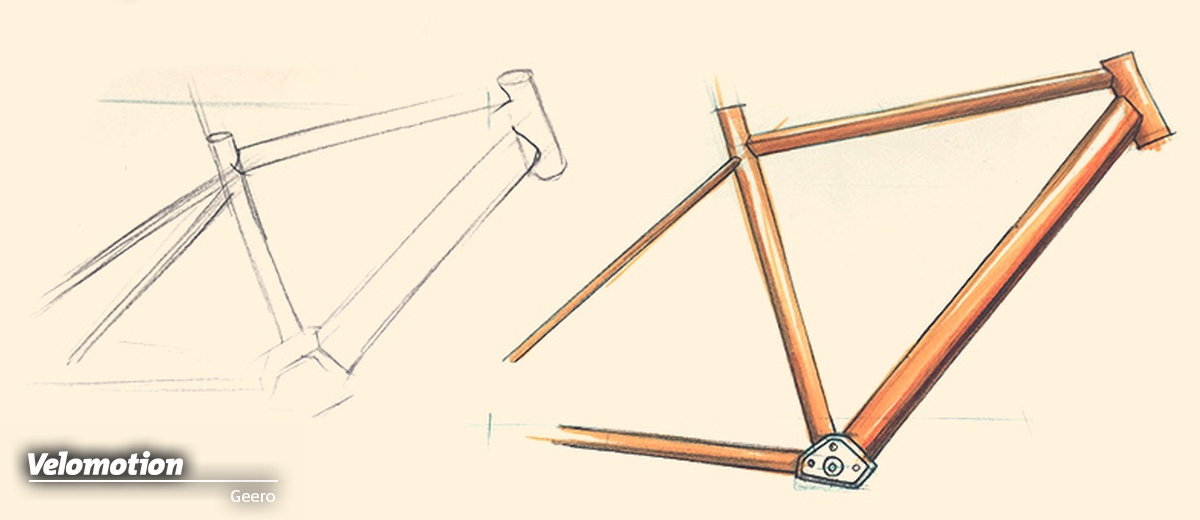

Wir schreiben das Jahr 2016. Mit Geero betritt ein Newcomer aus Österreich die E-Bike-Bühne, dessen erstes Bike spannende und für damalige Verhältnisse fast einzigartige Eckdaten mitbringt: Schlanke Rohre, ein kompakter, integrierter Akku, geringes Gewicht und einen Motor, der eher auf Natürlichkeit denn unbändige Unterstützung setzt. Das alles klingt wie eine Buzzwords-Sammlung aus dem E-Bike Marketing-Leitfaden für 2021 – ist aber gut fünf Jahre her, eine kleine Ewigkeit im Fahrradgeschäft. Nur zur Einordnung: Bosch sollte erst im Folgejahr erstmals in den Rahmen integrierte Akkus vorstellen, Mittelmotoren wogen alle weit über 3 Kilogramm und bei quasi allen E-Bikes stand noch immer die größtmögliche Power ganz vorn im Lastenheft. Dass sich bis heute viel getan hat, bei der Technik der Bikes ebenso wie in den Köpfen ihrer Fahrer und Konstrukteure, dürfte kein Geheimnis sein: Schlanke, leichte E-Bikes wie das Geero sind voll im Trend.

Rückblickend wird klar: Die Österreicher waren ihrer Zeit definitiv voraus und der Mut, sich gegen damalige Trends zu stellen, zahlt sich bis heute aus. Im vergangenen Jahr hat man mit dem Geero 2 den Nachfolger des Ursprungsmodells präsentiert, der zwar einige neue Features wie einen entnehmbaren Akku mitbringt, in seinen Grundzügen jedoch unverändert geblieben ist – dennoch: Auch im Jahr 2021 noch ein technisch wie optisch überzeugendes und modernes E-Bike, das mehr im Trend liegt als je zuvor. Davon konnten wir uns auch erst kürzlich in unserem Test überzeugen.

So spannend das Produkt „Geero“ jedoch auch sein mag, lohnt ebenso ein Blick hinter die Kulissen des Herstellers aus der Steiermark. Auch hier macht man nämlich so einiges anders als weite Teile der Konkurrenz und setzt voll auf regionale Produktion und direkten Kundenkontakt.

Hinter Geero stehen vor allem das Brüderpaar Michael und Tomy Rath. Mit ihrem Unternehmen Bikee stellen sie schon seit 2010 Motoren für E-Bikes her und für das Projekt „Geero“ haben sie sich mit den E-Commerce-Spezialisten von niceshops GmbH zusammengetan. Der Ursprung als bodenständiges Familienunternehmen, das seinen Anfang im heimischen Bauernhof nahm (der heute übrigens noch immer als Entwicklungszentrum dient) prägt den Kurs bis heute und ist Teil der Unternehmensphilosophie. So liegt der Produktionsstandort von Geero bzw. Bikee unweit der Heimat, ca. 20 km südlich von Graz, dazu kommt ein Showroom in Graz, von dem aus man auch eine Probefahrt unternehmen kann. Seit mittlerweile 2018 finden fast alle Produktionsschritte in Österreich statt. So wird direkt vor der heimischen Haustüre aus unzähligen Einzelteilen ein fahrbereites E-Bike.

Die regionale Produktion stärkt aber nicht nur die heimische Wirtschaft und verkleinert durch eingesparte Transportwege den ökologischen Fußabdruck – sie hat auch ganz handfeste Vorteile für Geero und deren Kunden. Service-, Reparatur- und Wartungsarbeiten können hier schnell und flexibel durchgeführt werden, zudem kann man flexibel auf Veränderungen am Markt reagieren, um beispielsweise wechselnde Nachfragen besser bedienen zu können.

Zu kaufen gibt es die schicken Geero Bikes ausschließlich beim Hersteller selbst. Das Direktvertriebs-Konzept macht es möglich, regionale Produktion und eine attraktive Preisgestaltung unter einen Hut zu bekommen. Dank des 2019 ins Leben gerufenen Band Manager Konzepts entfällt auch ein ganz wesentlicher Nachteil des Direktvertriebs: An ca. 30 Standorten in Deutschland und Österreich kann man eine Probefahrt vereinbaren – schön!

Im Laufe der Saison steht für uns noch ein Besuch in der Steiermark auf dem Plan – wir freuen uns darauf, die Produktionsstätte von Geero selbst in Augenschein nehmen zu dürfen.

Schreibe einen Kommentar